Table of Contents

What Is Cutting Technology?

Cutting technology encompasses the tools, systems, and processes businesses use to divide materials—ranging from metals to composites—into precise shapes for use in manufacturing and construction. Over the last decade, innovations in machine design and digital control have allowed companies to achieve new levels of accuracy and efficiency, reducing waste and driving down production costs. To remain competitive, businesses should get the services of experts at https://bluegrassbit.com/ when considering investments in advanced cutting solutions. Finding the right cutting technology means understanding current requirements and anticipating future growth and industry trends. Selecting equipment that aligns with both present and future production demands can increase operational flexibility and drive sustainable success.

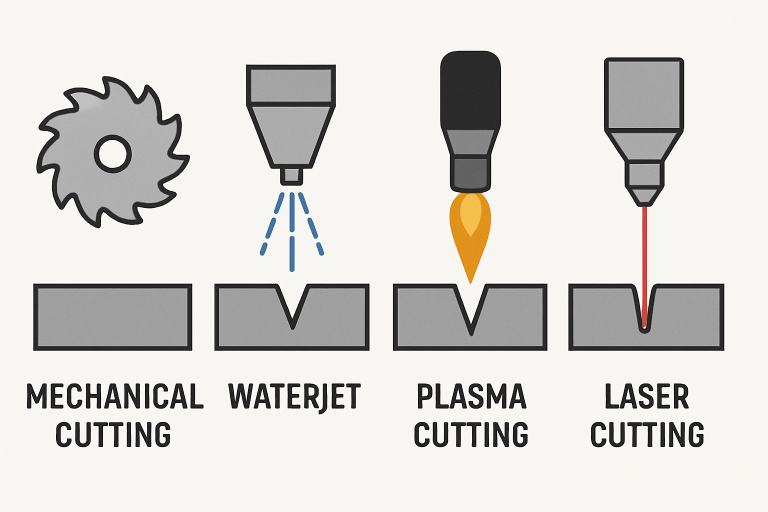

Types of Cutting Technologies

Manufacturers now have access to an array of cutting techniques, each suited to particular applications. Mechanical cutting, which utilizes saws and shears, is simple and effective for basic jobs. Abrasive waterjet cutting uses high-pressure streams of water mixed with abrasives to slice through thick, sensitive, or heat-sensitive materials with little material deformation. Plasma cutting is especially useful for conductive metals and offers fast throughput, while laser cutting stands out for its high precision, tight tolerances, and suitability for intricate shapes. Determining which method best fits your operation depends on your business size, typical material types, and the finish quality your clients or industry demand. In some sectors, hybrid technologies or advanced CNC (computer numerical control) systems integrate several of these methods, offering expanded versatility and control. Ultimately, a thorough comparison of methods based on workflow needs and industry standards is essential before making a purchase or upgrade decision.

Factors to Consider When Selecting Cutting Technology

- Material Thickness and Composition: The toughness, hardness, and thickness of the workpiece significantly affect technology choice. For example, waterjet is ideal for composites or glass, while plasma excels with thicker metals.

- Precision and Tolerance Needs: Opt for laser or advanced waterjet systems if you manufacture parts with tight standards, such as those used in aerospace or medical devices.

- Production Speed: High-volume manufacturing environments may prioritize throughput, swaying the decision toward plasma or automated laser solutions.

- Operational Costs: Factor in maintenance, labor, consumables, and possible downtime. It’s not just about the initial price tag—ongoing costs strongly influence the total cost of ownership.

Cost Versus Value Analysis

Although sophisticated cutting machinery can require substantial upfront investment, these systems often generate significant returns in the long run. Automated and precision-cutting equipment reduces labor costs, minimizes waste, and shortens delivery timelines. According to a report from SME, automation in cutting systems can improve productivity by as much as 60%, enabling faster order fulfillment and enhanced customer satisfaction. Businesses should undertake a comprehensive ROI analysis—considering factors like reduced scrap, lower rework costs, and equipment longevity—to inform their decisions. Consider how scalable the technology will be over time. Will it flex to meet rising demand or new product lines? Choosing robust, adaptable cutting technology may require a higher initial outlay but can ultimately support business growth and diversification.

Assessing Material Requirements

The spectrum of materials a company processes will directly impact technology selection. If your current production relies primarily on steel, you may find plasma or laser cutting most suitable. However, businesses anticipating diversification or expansion into markets—such as automotive, architecture, or consumer goods—should look for machines capable of handling a range of materials, including non-metals and composites. Prioritizing flexibility can reduce the need for costly upgrades or separate systems down the line.

Energy Efficiency and Safety

Rising energy prices and stricter regulations make energy consumption a key consideration. Opting for equipment designed to operate with reduced power consumption not only helps meet sustainability goals but also lowers operational spending. Leading systems now feature energy-management software, automatic power-down, and other eco-friendly attributes. Investing in energy-efficient technology can have a measurable long-term impact on business viability and environmental responsibility. Safety is equally vital; integrated dust extraction, safety enclosures, and automatic shutdown features help reduce workplace incidents and meet industry safety standards. These considerations should weigh heavily during the selection process.

Trends in Cutting Technology

The industry is seeing exciting developments in software integration, automation, and sustainable manufacturing. Smart cutting solutions with real-time data feedback enable process optimization, error reduction, and predictive maintenance. Automated systems reduce reliance on skilled labor and speed up repetitive processes, while advances in eco-friendliness—such as cleaner energy usage and optimized material utilization—help companies future-proof their operations. Keeping abreast of these trends ensures that investments made today will not become obsolete tomorrow.

Steps to Make an Informed Decision

- List your primary and future material types and expected production volumes.

- Research various cutting methods relevant to your materials and workflow.

- Solicit feedback from industry peers, case studies, or third-party reviews to gather real-world perspectives.

- Where feasible, run small-scale trials to evaluate system integration into existing workflows and gauge operator learning curves.

- Weigh the initial investment against long-term benefits—factoring in scalability, vendor support, and potential ROI.

Dedicating time to this evaluation process increases your chances of finding technology that fits your current needs, adapts as you grow, and consistently supports your company’s reputation for precision, reliability, and efficiency.

Conclusion

Choosing the right cutting technology is not just a matter of purchasing equipment—it is a strategic decision that directly impacts productivity, cost efficiency, and long-term competitiveness. Businesses can align technology choices with present operations and future growth by carefully weighing material requirements, precision needs, energy efficiency, and safety standards. Advances in automation, sustainability, and smart manufacturing make it even more critical to stay informed about industry trends. Ultimately, the best decision comes from balancing cost with value, ensuring flexibility for evolving markets, and investing in systems that drive precision, reliability, and innovation.