Table of Contents

Introduction

Ensuring your rig maintains peak performance and adheres to rigorous safety standards is vital for any operator. Over time, even the most robust equipment will face the challenges of age, heavy use, and evolving industry requirements. Whether due to daily wear and tear or changing regulations, timely upgrades and reinforcements can mean the difference between seamless operation and costly downtime. With solutions available from suppliers specializing in critical infrastructure—such as drilling rig derrick supplier for jack-up and semisubmersible rigs—operators have access to expertise and high-quality components tailored to their unique rig needs.

Properly timing your upgrades is crucial to keeping your crew safe, reducing maintenance expenses, and staying competitive in today’s oil and gas sector. Understanding the signs that signal a need for modifications and knowing how to evaluate and implement changes can extend the useful lifespan of your assets while protecting your investment and reputation.

Signs It’s Time to Upgrade

- Frequent Breakdowns: Persistent mechanical issues and increased downtime often indicate that vital rig components are approaching the end of their useful life. Ignoring these symptoms not only impacts productivity but also risks more catastrophic and costly failures on-site.

- Rising Maintenance Costs: If repair bills are climbing steadily and outpacing budget expectations, it’s time to compare the cost of frequent fixes against the cost of investing in upgrades or replacements. Upgrades may be a more cost-effective approach than investing funds in obsolete equipment.

- Outdated Technology: The industry’s rapid technological advancements mean yesterday’s standard features may no longer meet today’s efficiency or safety expectations. Upgrading gives your rig access to better controls, automated systems, and enhanced data analytics for streamlined operations.

- Compliance Issues: Stringent and regularly updated regulations require rigs to meet the latest safety and environmental standards. If your rig cannot easily comply with new rules, modifications or reinforcements may be necessary to avoid costly fines or legal complications.

Noticing these warning signs and acting proactively can save you from unplanned outages, significant financial losses, or jeopardizing crew safety.

Evaluating Upgrade Options

When your rig begins to show its age or struggles to meet new requirements, it’s important to evaluate your upgrade options systematically:

- Structural Integrity: Begin by determining whether your rig’s core construction is capable of supporting new modifications. Additional loads from new equipment or accessories must not compromise the overall integrity of the platform.

- Compatibility: All upgrades should integrate seamlessly with the current systems—mechanical, electrical, and digital—to prevent new issues from arising after installation.

- Cost-Benefit Analysis: Compare the total cost of an upgrade (including installation and any lost revenue from downtime) with the cost of purchasing new equipment outright. Sometimes, incremental enhancements offer a better return; other times, replacement is the only viable option.

Deep dives into cost assessments can help balance the upfront investment with anticipated savings, productivity improvements, and increased longevity of your existing rig.

Common Modifications and Reinforcements

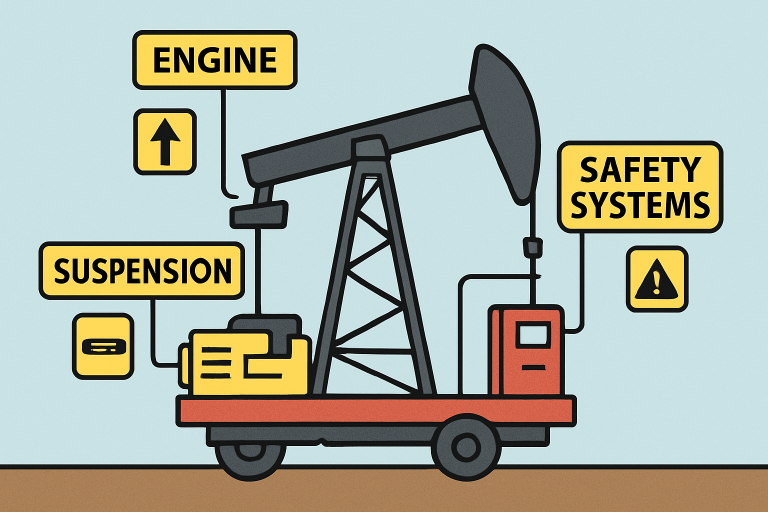

Upgrades can involve minor adjustments or total overhauls, depending on operational needs. Some frequently applied modifications include:

- Engine Upgrades: Swapping out legacy engines for higher-performance models can deliver improved fuel efficiency, reliability, and compliance with new emission standards, while enhancing overall output.

- Suspension Enhancements: Reinforcing or replacing the suspension system allows your rig to safely manage heavier payloads or traverse rougher terrain, significantly reducing wear on the entire structure.

- Safety Features: Installation of advanced safety equipment—such as anti-collision systems, real-time monitoring sensors, and emergency shutoff modules—can help ensure compliance and reduce the risk of accidents.

Safety Considerations

Above all else, prioritizing safety throughout the upgrade process is non-negotiable. Regular inspections before, during, and after modifications are necessary to ensure new components integrate correctly and that the rig’s operational integrity is never put at risk.

Planning and Implementation

Effective upgrades start with a disciplined and structured approach:

- Assessment: Conduct an in-depth analysis of current performance to pinpoint areas that need attention or improvement.

- Research: Leverage supplier and manufacturer knowledge, industry reports, and case studies to find technologies that meet both operational and regulatory goals.

- Budgeting: Create a realistic budget that accounts for equipment costs, installation fees, training requirements, and potential downtime.

- Execution: Roll out upgrades systematically, inspecting and validating each modification to guarantee performance and safety benchmarks are achieved before resuming full operations.

Effective communication and collaboration between site managers, engineers, and suppliers ensures that each step of the implementation aligns with your overall operational objectives.

Final Thoughts

Staying ahead in a fast-evolving sector requires vigilance, expertise, and a willingness to invest in timely upgrades for your rig. By monitoring key performance metrics, adhering to safety protocols, and collaborating with reliable suppliers—such as a dedicated drilling rig derrick supplier for jack-up and semi-submersible rigs—rig owners can safeguard their investments, enhance safety standards, and maintain operational excellence for years to come.