Ensuring safety on construction sites is a top priority for every project manager. The construction sector faces numerous hazards every day, including falling debris, the spread of dust, and exposure to hazardous materials. Among the many safety practices available, one highly effective tool is often underutilized—the construction debris tarp. These robust and reliable covers are engineered not only to contain hazardous material but also to safeguard workers, minimize environmental impact, and help projects proceed efficiently. From covering heavy equipment to forming physical barriers that prevent on-site accidents, a construction debris tarp streamlines overall job site management and keeps safety at the core of daily operations. By integrating tarps into standard protocols, companies not only adhere to stringent safety regulations but also foster a culture of safety, improve team morale, and increase productivity, which is crucial for meeting project delivery timelines and maintaining client trust.

Debris tarps provide much more than just a dust- or rain-shield from falling objects. Their actual impact is evident across the full spectrum of construction site management—yielding significant cost savings, fostering better site organization, and heightening security, all of which are increasingly vital in today’s demanding construction environment. Adopting thoughtfully designed tarp systems means companies can ensure compliance with evolving workplace safety laws, reduce the likelihood of regulatory penalties, and bolster their reputations for excellence. Additionally, a cleaner, more organized, and secure construction zone benefits everyone—contractors, clients, and communities alike.

Table of Contents

Containment of Hazardous Materials

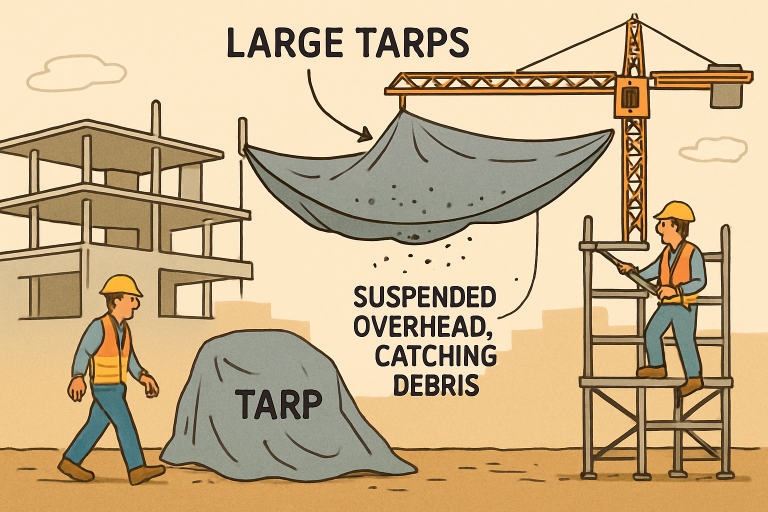

Construction and demolition sites generate a wide array of debris, ranging from fine dust and metal shards to larger objects, including broken concrete, nails, and even hazardous compounds such as asbestos fibers and lead-based paints. Without proper containment, these particles can easily escape into surrounding areas, significantly increasing health and safety risks for workers, as well as for neighboring residents or passersby. Durable debris tarps, designed from heavy-duty synthetic fibers, act as a reliable first line of defense by capturing falling and airborne debris before it can disperse. This dramatically reduces the risk of dangerous exposure, workplace injuries, and environmental contamination. Utilizing physical barriers and engineered containment systems is considered a best practice for mitigating health hazards associated with construction activities. The use of debris tarps can also help companies demonstrate due diligence in protecting public safety, a key consideration for regulatory compliance and risk management.

Protection Against Weather Elements

Adverse weather isn’t just an inconvenience; it can significantly disrupt construction schedules and create dangerous working conditions. Unpredictable rainstorms, strong winds, and intense sunlight all pose significant dangers: water can damage sensitive materials and electronics, powerful gusts can disperse loose debris, and excessive sun exposure can lead to heat-related illnesses among workers. Covering exposed equipment and vulnerable work areas with weather-resistant tarps helps ensure that construction can proceed safely regardless of the weather. High-quality debris tarps block UV rays, repel water, and act as windbreaks, thereby preventing heat stress in workers, avoiding mold or rot in stored materials, and keeping valuable machinery operational. The growing dependence on weather mitigation strategies, such as specialized tarps, is expected to increase as extreme weather becomes more prevalent in many regions. Ultimately, this proactive risk management safeguards both people and profits.

Maintaining Clean and Organized Worksites

Clutter and disorganization are significant contributors to worksite accidents and inefficiency, as documented by organizations such as the National Safety Council. Debris tarps make it easier to keep waste materials contained and necessary supplies protected from pilferage or damage. Crews can use tarps to segregate trash, recycling, and building supplies—resulting in designated drop zones and reducing the risk of mix-ups and misplaced tools. This organizational approach not only saves valuable time by preventing unnecessary trips across the site, but it also minimizes tripping and slipping hazards caused by scattered materials. A clean, orderly job site is not just safer—it supports faster search and retrieval of items, allows machinery clear access, and helps crews maintain focus on skilled tasks rather than on housekeeping. Well-organized sites project professionalism to clients and inspectors, which can lead to more future contracts and smoother project sign-offs.

Enhancing Site Security

Every construction site is inherently at risk for theft, vandalism, or unauthorized access, especially during evenings or weekends when direct supervision is reduced. Debris tarps deliver a two-fold security benefit. First, they conceal valuable equipment and supplies out of plain view, making it harder for opportunistic thieves or vandals to identify targets. Second, they create a physical barrier, slowing or preventing unauthorized entries and trespassing attempts. The simple presence of secured tarps sends a clear message that the site is monitored and protected, which can be enough to deter casual intruders. Additionally, when combined with fencing, CCTV, or alarm systems, tarps further help contractors meet insurance compliance requirements regarding on-site security. Insurance providers are increasingly attentive to proactive risk mitigation, and secure tarping can reduce premiums and avoid costs associated with theft or vandalism-related project delays.

Cost Savings and Efficiency

Investing in debris tarps promotes more than just safety—it also yields impressive financial benefits. Consider the cumulative cost of project delays, rework, or equipment replacement due to contamination, weather, or theft. Tarps help avoid these pitfalls by protecting everything from delicate tiles to expensive machinery, preventing damage and unnecessary downtime. Efficient cleanup, thanks to debris containment, also reduces labor hours spent on site maintenance. Less time diverted to repairs and cleaning means projects are more likely to remain on schedule, with skilled laborers able to focus on their core tasks instead of constantly cleaning up. This efficiency translates directly into cost savings, with fewer insurance claims, reduced administrative burden, and a more reliable project timeline. In a competitive market, this can be a decisive advantage for contractors.

For construction professionals, incorporating debris tarps into safety and project management plans is a straightforward yet high-impact measure. These innovative solutions deliver benefits on multiple levels—protecting workers, preserving valuable equipment, ensuring workflow continuity, and reducing both direct and indirect project costs. With such sweeping, measurable advantages, debris tarps are an essential and wise investment for any construction job site, and no contractor concerned with safety and efficiency should overlook their importance.