Building sustainable roads is quickly becoming a necessity as communities and contractors seek ways to minimize environmental impacts while maintaining high-quality infrastructure. The right material selection ensures not only a longer-lasting road but also more environmentally friendly construction practices. If you are wondering how to choose the best sustainable material for your next road project, this comprehensive guide provides the key insights to make informed decisions.

From understanding the environmental effects of traditional choices to evaluating recycled and innovative options, this article explores the benefits, challenges, and suitability of each sustainable material. These insights are crucial for planners, engineers, and stakeholders seeking projects that are both effective and environmentally responsible.

Table of Contents

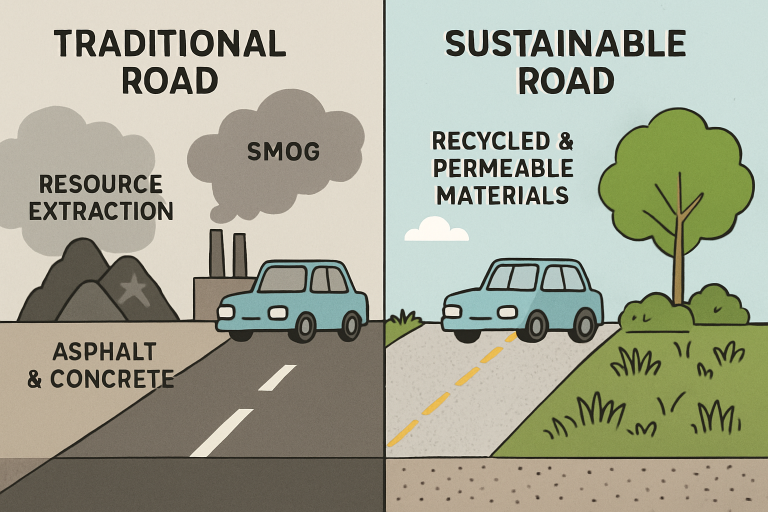

Traditional Materials and Their Impact

For decades, asphalt and Portland cement concrete have been the primary materials used in road construction. While they provide proven strength and durability, the environmental costs are substantial. Asphalt relies on non-renewable petroleum resources, and its manufacturing releases volatile organic compounds (VOCs) and other pollutants into the atmosphere. Meanwhile, the global production of Portland cement is responsible for approximately 8% of the world’s carbon dioxide emissions, making it a significant contributor to climate change, according to the BBC.

Extracting raw materials for these traditional roads also leads to habitat destruction, resource depletion, and significant energy use. The pressure to reduce these adverse effects is spurring the search for more sustainable alternatives that conserve resources and reduce emissions.

In addition to greenhouse gas emissions, the disposal of old pavement materials in landfills creates additional environmental burdens. This reality is paving the way for solutions that focus on recyclability, repurposing, and longevity.

Regulations and public expectations are shifting, making sustainability not just a preference but an increasingly necessary component of civil engineering and construction. Adopting greener materials can help projects gain approval more easily and demonstrate a commitment to the community and the environment.

Recycled Asphalt Pavement (RAP)

Recycling asphalt pavement is a practical solution that addresses both waste and emissions reduction. RAP is produced by milling existing asphalt layers and reintroducing the reclaimed material into new pavements. This process reduces the need for new raw materials and sharply cuts down on landfill waste and energy consumption.

Benefits of RAP

- Conserves non-renewable natural resources.

- Reduces greenhouse gas emissions—potentially by up to 50% depending on the process.

- Often lowers overall project costs by decreasing the quantity of virgin materials required.

- Roadway performance can be improved with proper blending and engineering.

Agencies such as the Federal Highway Administration strongly endorse the use of RAP, citing its proven performance over decades of use.

Recycled Concrete Aggregate (RCA)

Another essential material for sustainable roads is RCA, derived from crushing concrete from demolished buildings, roads, or bridges. Rather than sending this debris to landfills, RCA repurposes it as base layers or sub-bases for new projects.

Key Features of RCA

- Reduces landfill volume and conserves virgin aggregate sources.

- Offers similar structural performance to traditional aggregates when properly processed.

- It can sometimes contain reinforcing steel, further contributing to material reuse.

- Supports a circular economy strategy for the construction industry.

Warm-Mix Asphalt (WMA)

WMA introduces innovative additives or processes that allow asphalt mixtures to be produced and laid at lower temperatures. This method reduces energy use by up to 35% and improves workability, making it especially useful during colder seasons.

- Decreases emissions of CO₂ and VOCs during production and paving.

- Extends paving seasons and allows for earlier traffic reopening.

- Improves worker safety by reducing fumes and contact with hot surfaces.

WMA is gaining traction globally as contractors and public works agencies aim for lower-carbon construction solutions.

Geopolymer Concrete

For roads and pavements that require high strength and durability, geopolymer concrete offers a compelling and sustainable alternative. Unlike traditional concrete, geopolymer concrete uses industrial by-products such as fly ash, blast furnace slag, or silica fumes, which are combined with alkaline activators to form a solid binder.

Advantages

- Reduces embodied CO₂ significantly compared to Portland cement concrete.

- Offers superior fire, chemical, and sulfate resistance, contributing to longevity and lower maintenance needs.

- Encourages the reuse of waste products from other industries, closing material loops.

Geopolymer concretes can reduce carbon emissions by over 50% compared to standard options, especially when using high proportions of industrial by-products.

Permeable Pavements

Urban development often exacerbates the challenges of flooding and stormwater runoff. Permeable pavements allow rainwater to pass through their surface into underlying layers, helping recharge groundwater tables and reduce the load on stormwater systems.

Main Benefits

- Reduces surface runoff, alleviating flood risk in cities.

- Supports healthier urban water cycles and can moderate local temperatures by reducing the heat island effect.

- Decreases the burden on municipal drainage infrastructure during heavy rains.

- Can be constructed from permeable concrete, open-graded asphalt, or interlocking pavers.

Many municipalities now require permeable pavement solutions in new urban developments for sustainable stormwater management.

Emerging Technologies

The push for sustainability is fueling significant innovation in road materials. Self-healing asphalt, for example, uses additives that enable the pavement to repair small cracks autonomously, potentially doubling its lifespan. Meanwhile, carbon-cured concrete traps and stores captured CO₂ during the curing process, not only strengthening the pavement but also permanently sequestering carbon.

These technologies are still evolving, but pilot projects show promising results. As adoption grows, they are likely to become integral parts of sustainable construction standards.

Conclusion

Selecting the right sustainable materials is vital for environmental stewardship and the resilience of our road networks. By tapping into recycled materials like RAP and RCA, exploring innovative solutions such as WMA and geopolymer concrete, and supporting emerging technologies, road construction can not only reduce emissions and conserve raw materials but also lower life-cycle costs and improve community outcomes.

Future projects that prioritize sustainability will benefit communities, ecosystems, and economies for generations to come.